Coverlay Voids �?To forestall wear, coverlay voids must be minimized in spots the place traces are uncovered. Strategic placement of voids should be viewed as in dynamic bend zones.

More dielectric stiffening levels may very well be included in multilayer constructions to attenuate flex PCB wrinkling or buckling because of thermal stresses.

two) Electric Conductors: These include traces with the circuit, copper foil is applied because the area conductor levels from the production of solitary/multilayer printed circuit boards.

Dave went through a number of facts even though developing the PCB And eventually exhibiting the best way to get from a company, PCBway.

With Every passing 12 months, the demand from customers for more strong computing technology grows. Even so, individuals from all industries anticipate superior overall performance with more compact weight and dimension constraints.

The most common and applied sort of Printed Circuit Boards is definitely the rigid variety, however the flex one is an additional style that you just may think about using it soon after getting on your own acquainted with, In particular that it's now much more available than just before as additional producers are delivering this kind.

All things considered, it is time for you to add your design information and submit your buy. If you want to see a up coming post about flex PCB layout, tips on how to deliver style information and Placing an get, then state that within the reviews portion.

These abilities permit flexible circuits to satisfy the sophisticated physical and electrical demands in compact, moveable electronic equipment.

Flex boards can be used as connectors, and as full circuits assembled with parts. And Sure it could keep the soldering heat In addition it can stand way much more than rigid types with large temperature based on the made use of film product variety.

When it can be applicable, reliable polygons must be averted as reliable copper is likely to make the PCB a lot less flexible. As a substitute, a hatched polygon could be made check here use of, such as graphic underneath.

Flex PCB designers will need resources which make it as easy as feasible to handle the intricacies of flex and rigid-flex constructions. Built-in solutions from main vendors deliver the capabilities to architect intricate flex and rigid-flex boards.

IPC-2581 serves as being a important regular from the Trade of data for that manufacturing of flexible PCBs. As an open, seller-neutral XML structure, it performs a pivotal function in navigating the intricate constructions of flex PCBs, facilitating sleek exchanges of style knowledge encompassing layer stack-up, drill details, and also other technical specs.

Although giving various advantages, flexible PCB technological innovation also provides the subsequent limits:

Flexible Heaters �?Pattern resistive heating things on flex substrates to build skinny heating pads and blankets effective at conforming to surfaces.

YouTube

Twitch

Gravatar

Issuu

Instapaper

AnyFlip

Mixcloud

Sun Community News

Western City Jobs

Wakelet

Replit

Sketchfab

Docker Hub

Qiita

Babelcube

M5Stack Community

Data World

Gifyu

Matters Town

ArchDaily

Ariana Richards Then & Now!

Ariana Richards Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Christina Ricci Then & Now!

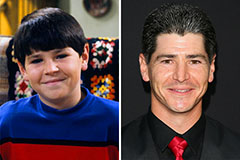

Christina Ricci Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now!